In this guest blog post, Joan Fearnley, a soprano, a choir director, and the creator of the open source “Singer’s Mask” pattern/design, teams up with MakerMask to discuss some of the science and special considerations for masks for singers. The five sections of this post answer key questions about masks for singers:

- Does singing require different masks than talking? “Singing, Science, and COVID”

- What makes masks for singers special? “5 Design Considerations for Masks for Singers”

- Where can I get masks for singers? “Making or Buying Masks for Singers”

- Which fabrics should I consider? “Three-Layer Masks for Singers – Fabrics and Layers”

- How do I care for masks for singers? “Masks for Singers – Care & Use”

Singers wear masks for the same reason as the general public, to help slow the spread of COVID-19. These masks are designed to contain the user’s droplets, must be breathable, should fit snugly to the face, and should not interfere excessively with sound production. Masks for singers are recommended in addition to social distancing, frequent hand washing, shorter rehearsals and proper ventilation [CDC, 2020; WHO, 2020].

Singing, Science, and COVID-19

As most singers know well, choir practices (like other unmasked indoor group activities) have been associated with large COVID-19 transmission events [Naunheim, 2020, Miller et al, 2020; NCCEH, 2020]. Research on respiratory droplets and aerosols suggests that more particles are emitted by vocalizing (e.g., singing and talking) than by breathing alone, and that loud vocalizations generate more particles than quiet vocalizations [Asadi et al, 2019; Alsved, 2020; Gregson et al, 2020]. Although initial studies show that loose fitting masks can reduce particle emissions associated with singing, improved performance is expected from well-fitted masks designed specifically for singers [Alsved, 2020].

For those interested in more information about the science, these review articles are a good place to start:

“Safer Singing During the SARS-CoV-2 Pandemic: What We Know and What We Don’t”, Naunheim MR et al., J Voice. 2020;S0892-1997(20)30245-9.

“COVID-19 Risks and Precautions for Choirs”, National Collaborating Centre for Environmental Health (NCCEH), Canada.

Five Design Considerations for Masks for Singers

In this section we’ll discuss some of the special requirements for those making or buying masks for singers, including fit, structure, breathability, filtration, and acoustics

#1. Mask Fit

Singing requires larger jaw movements than normal conversational speech (e.g., the low mandible maneuver) [Mercer et al, 2020]. As a result, masks for singers need to be designed with extra fabric around the chin to accommodate these jaw movements and ensure that the mask stays in place without shifting and losing the snug fit. The incorporation of this extra fabric means that masks for singers generally have more surface area than typical masks, which has the added benefit of increasing the overall breathability of the mask as well.

#2. Mask Structure

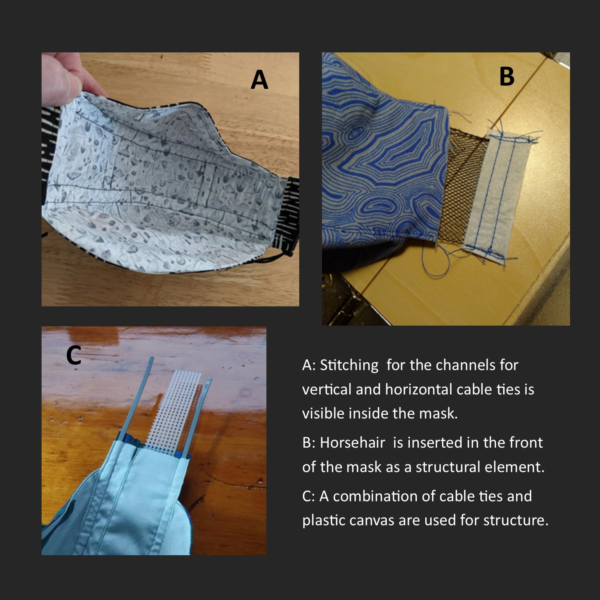

Singing requires more rapid inhalations than breathing or talking [Salomoni et al, 2016; Alsved, 2020]. To prevent mask fabrics from getting sucked into the mouth when singers inhale, and to allow for free articulation, masks for singers incorporate semi-rigid elements such as boning, cable ties (zip ties), crafting plastic mesh, or horsehair (plastic mesh used in dressmaking). These elements add structure to the mask that holds the mask fabrics away from the mouth and nose. However, they may require special handling when cleaning/disinfecting (see care & use section for details).

#3. Mask Breathability

Singing requires larger peak air flows than breathing or talking [Salomoni et al, 2016; Alsved, 2020]. Singers are vocal athletes, and like other athletes require more breathable masks than those designed for activities with less vigorous air exchange [NCCEH, 2020]. However, singers have different breathing dynamics and timing relative to most athletes because singers require fast deep inhalations and long continuous exhalations [NCCEH, 2020]. Although added structural elements help with the breathability requirements, the fabric layers used in masks for singers need to allow the rapid passage of air. Breathability in masks for singers is primarily addressed through appropriate selection of mask materials and layering combinations that optimize breathability without compromising filtration (see mask layering section for more information).

Moisture from the wearer’s breath may also decrease breathability. Fabrics and layering combinations should take into account this increased moisture accumulation associated with the vigorous air exchange and droplet generation of singing. To address issues of breathability and moisture accumulation without compromising filtration, fabrics with the best filtration characteristics are used for the middle or outermost (furthest from the mouth) mask layers [Health Canada, 2020; WHO 2020].

#4. Mask Filtration

Singing may increase exhaled droplets and particles relative to talking because singing requires deeper breaths, more airflow, more continuous voicing, and higher sound levels [Alsved, 2020; Asadi et al, 2019; Salomoni et al, 2016]. As such, masks for singers should pay special attention to mask filtration properties. This is accomplished by careful consideration of mask materials and layering combinations. Although some health agencies still suggest masks with at least two layers (CDC, 2020), an increasing number of health agencies are recommending at least three layers to help improve filtration [Health Canada, 2020; WHO 2020].

Deeper Dive: Filtration Standards for Fabric Masks

Navigating the research on filtration for fabric masks can be confusing because test results vary significantly depending on test methods AND the particle size tested. However, emerging standards from the WHO, AATCC, and others suggest that at a minimum fabric masks should aim to achieve a particle filtration efficiency (PFE) of at least 70% for three microns particles [AATCC M14-2020; WHO, 2020]. This particle size is similar to the particle size requirements for surgical masks, which are expected to provide 95% filtration for particles in the 1-3 um range whereas N95s are designed to provide similar particle filtration efficiency for much smaller particles in the 0.1-0.3 um range.

In addition to guidelines available from different national and international agencies, the American Society for Testing and Materials (ASTM) released standards for filtration, breathability, and reuse that are applicable to fabric masks. For more information see “New ASTM Standard for Face Coverings: ASTM F3502″.

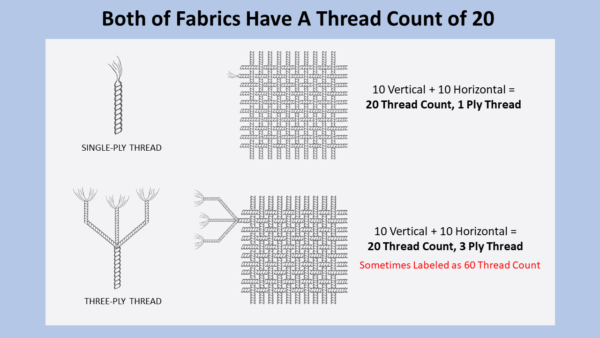

While the science around the best fabrics for sewn masks is still evolving, current data suggest that some fabrics that are accessible to home sewists are more effective for containing droplets than others [Zangmeister, 2020; Zhao, 2020; WHO, 2020]. In general, the fabrics that perform best are tightly woven fabrics (≥ 200 threads per inch) and non-woven fabrics.

#5. Mask Acoustics

Singing is dependent on quality acoustics. Unfortunately, the types of fabrics that block and absorb droplets also block and absorb sound. A balance of these two opposing goals is addressed through fabric selection and layering. Highly breathable fabrics (whether woven or nonwoven) typically have the best acoustics [Soltani, 2013; Corey, 2020A; Corey, 2020B]. An advantage of nonwoven polypropylene (NWPP) fabrics is that they have a good balance of breathability, filtration and acoustic properties [Zhou et al, 2020; Long et al, 2020].

The Lombard Effect is the tendency of both speakers and singers to increase the sound level (dB) of their voices in situations where their vocalizations are muffled [Tonkinson, 1994]. When masks muffle the sounds associated with speech and/or singing, people tend to increase the sound level of their vocalizations to compensate, which may increase droplet and aerosol production [Asadi, 2020].

For singers, the best masks will incorporate features that address each of these five considerations as well as guidance from local, regional, national, and international public health officials.

Making or Buying Masks for Singers

As regional authorities and institutions have imposed mask wearing policies, singers and other performing artists have had to source masks to suit their needs. They have the option of either sewing the masks for themselves (or partnering with a sewist), or purchasing masks from a seller.

Sew-Your-Own Mask

Joan Fearnley has created patterns and tutorials freely available on her YouTube channel. She has also created a Facebook group “Masks for Performers” where she fosters an open source approach so that innovations and additional patterns can be shared freely by the community. Having a pattern freely available has been appreciated by many choirs where teams of volunteers have sewn these masks at minimal cost.

Tips for Mask Makers:

- Stitching: A good mask will have tight stitching to avoid leakage of air/particles through the seams. Avoid vertical seams/stitch lines in the center area of the mask over the mouth and under the nose [AFNOR Spec 276-001, 2020]. Ensure there is no gaping or puckering between stitches that would allow unfiltered air to leak through.

- Pinning: Limit pinning where possible. Consider using fabric clips instead, or use the smallest pins possible and pin inside the seam allowance.

- Labelling: If you are making masks for other people be sure to include a label with each mask that contains information about any body contacting materials used as well as instructions for cleaning and/or disinfecting the masks. Click here for more information on mask labeling.

Purchase a Mask

A number of different purchasing options are available. Many mask makers have adopted and sometimes adapted Joan Fearnley’s patterns and added them to their regular mask offerings. Other suppliers have independently created their own patterns. Two of these, the Broadway Mask and the Resonance Mask, are worth noting because they have undergone testing by Colorado State University (CSU), as described below.

Colorado State University Filtration Results (click here for interactive graph). CSU has tested a number of cloth masks, including two of the commercially available singer’s masks (The Broadway Relief Project Singer’s Mask and the Resonance Singer’s Mask) using methodologies consistent with those recommended by the AATCC and the WHO (particle size from 0.5um – 12 um).

- The Broadway Relief Project Singer’s Mask is a three-layer mask (medium weight cotton muslin, nonwoven polyester interfacing, medium weight cotton muslin) with an “airflow window” through the middle layer that is intended to make the mask more breathable. However, the airflow window allows both air and particles to escape as they follow the path of least resistance through the two layers of fabric at these side windows. According to the CSU data, the filtration of the Broadway mask for 3um particles is ~70%, which satisfies AATCC filtration requirements. It also passes breathability recommendations, with a pressure drop of 4.6 mm H20 across the mask.

- The Resonance Singers Mask is a two-layer mask (“high thread count” cotton outer layer and a “wicking, technical knit polyester/bamboo fabric” on the inside) with an optional filter insert. While an increase in filtration is likely with the addition of the filter, the overall efficacy will depend on the fit of the filter within the mask. The filtration performance of the Resonance masks (without the optional filter) was ~40% at 3um. It also passes breathability recommendations, with a pressure drop of 1.3 mm H20 across the mask.

Three-Layer Masks for Singers – Layering & Fabrics

Although the “best” combination of fabrics and layers for non-medical masks (used for source control) is still under investigation, masks constructed from at least three layers of a combination of hydrophobic (water resistant) and/or hydrophilic (absorbent) fabrics are gaining traction because they offer a good balance of comfort, filtration, and breathability [WHO 2020; Health Canada, 2020; Australia, 2020; Songer, 2020].

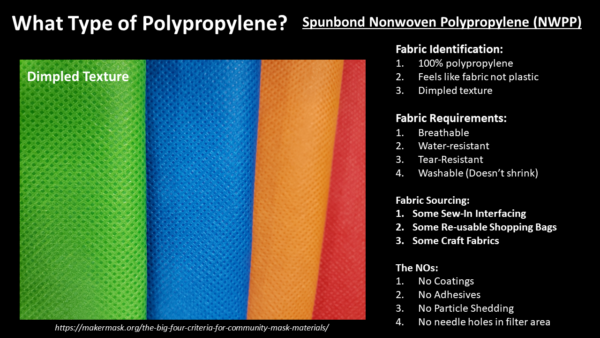

- Hydrophobic layers (e.g., nonwoven polypropylene – NWPP) help contain the users respiratory droplets, aid with filtration, and may help prevent droplets from penetrating through the mask to the user [WHO 2020; Songer, 2020]. Hydrophobic nonwoven materials are frequently recommended for the middle layer (see Health Canada y WHO guidance) and/or the outermost layer of masks (see Australian y WHO guidance).

- Hydrophilic layers (e.g., tightly woven cotton) help absorb the users droplets and may aid with filtration. Tightly woven cotton materials are frequently recommended for use in the mask layer that is closest to the face (see WHO 2020, Health Canada, Australian, and CDC guidance) and is sometimes recommended for the outermost mask layer (see Health Canada).

Masks for singers are designed to meet the specific needs of singers for source control in areas where universal masking and social distancing are ensured. The “Singer’s Choice” materials and layers described below have been optimized for use by singers in real-world environments and are consistent with nonmedical fabric mask recommendations from the WHO, Health Canada, and the CDC (as of November 5, 2020).

Click on the box below to review the meaning of fabric weights and measures like grams per square meter (gsm) and thread count!

Layer 1 – Closest to the Face

The innermost mask layer is designed to be comfortable against the skin and to absorb the large droplets generated by the mask user. Over time this layer becomes damp and breathability may decrease. Due to the higher level of moisture this layer is exposed to, it may make sense to use either nonwoven polypropylene (NWPP, 40 – 70 gsm) or a medium weight cotton (120 – 180 gsm or 120 – 250 thread count) for this layer. Fabrics used for this layers are typically lighter/thinner than those used in the middle and outer mask layers.

- Singer’s Choice: 100% Cotton – Medium Weight (120 – 180 gsm; 120 – 250 thread count) such as a cotton poplin (~130 gsm with a thread count of 216 – 148 x 68 square) or a standard quilting cotton such as Kona cotton (~150 gsm with a thread count of 120 – 60 x 60 square) [AATCC M14-2020; WHO 2020].

Layer 2 – Middle layer

The middle layer is designed to act as a barrier to help contain the singer’s droplets and to provide filtration. For this layer a washable non-woven hydrophobic (water resistant) layer such as NWPP (~70 gsm), like some interfacing fabrics, is recommended [WHO 2020; Health Canada, 2020; MakerMask]. Using a water-resistant layer as the middle layer can also help keep outer layers dry, which may help improve their filtration capacity.

- Singer’s Choice – Spunbond NWPP (60 – 70 gsm): Best option is an undyed spunbond NWPP (~70 gsm). Although medical grade material is ideal, some NWPP is sold as sew-in interfacing (e.g., Cambric 915) and may be a reasonable option. Avoid fusible interfacing which contain adhesives and other additives [see MakerMask Materials for details]. If NWPP is not available, spunbond nonwoven polyester interfacing may be considered [WHO 2020; AFNOR, 2020]. As with all fabrics, NWPP will degrade with repeated washing/disinfection cycles. Although NWPP can be machine washed (70C) and dried on low, handwashing and air drying will extend the life of the fabric [WHO, 2020].

Filter Inserts: Many cloth masks offer the option of a removable/disposable filter as a middle layer. However, the added filtration benefit of filter inserts relative to sewn-in filters is unclear. This is because the effectiveness of the filter insert depends on how well it is sealed to the face and other mask layers. If there is sufficient possibility for leakage around the filter insert, airflow will follow the path of least resistance and escape around the filter instead of passing through it.

Layer 3 – Outer layer

The outermost mask layer is designed to offer additional filtration and/or water-resistance depending on which materials are used. MakerMask typically recommends using a hydrophobic material (≥ 70 gsm NWPP) as the outermost mask layer to help prevent droplets from penetrating through the mask to the user (Songer, 2020). However, in masks for singers that are used exclusively as source control in well-controlled areas where universal masking and social distancing are ensured, a tightly woven cotton may be considered [AATCC M14-2020].

- Singer’s Choice – Tightly Woven Cotton (≥ 190 gsm; >200 TPI): The most tightly woven cotton such as ≥ 400 thread count sheet/pillow cases, and batik (200-280 gsm; 220 threads per inch) will likely provide the best filtration, however heavy quilting cotton (180 picks per inch) and plain weave cotton (120-160 picks per inch) may provide a good balance of breathability and filtration [AATCC M14-2020].

“Pros & Cons of Other Fabrics”

- Flannels: The “fluff” typical of flannel has been shown to provide good filtration [Zangmeister et al, 2020]. However, flannels tend to be thick, warm, muffle sound, and are not very breathable when moist.

- Chiffon: Early research suggested that chiffon may be advantageous for mask filtration [Konda et al, 2020]. However, subsequent research [Zangmeister et al, 2020] calls these findings into question and suggests tightly woven cottons and flannels are more effective.

- Silks: Although it is possible to give silk an electrostatic charge by rubbing or ironing it, the functional relevance of this charge unclear because it dissipates quickly in high humidity environments (e.g., due to the moisture generated by the wearer’s breath) [Zhao et al, 2020; MakerMask- Electrostatics]. In general, hydrophobic materials hold electrostatic charges longer than silk [Zhao et al, 2020; WHO, 2020]. However, the process of rubbing the masks degrades the fabric over time, has to be performed prior to each use, and in all cases decays over time and when exposed to humidity [Zhao et al, 2020; WHO, 2020; MakerMask Fabrics- Electrostatics].

- Stretch fabrics (e.g., spandex, nylons, and knits): These materials have been used as outermost layers of masks to help improve the fit of the mask [Northeastern University, 2020]. However, the WHO recommends avoiding these materials because as they stretch, it increases the size of the pores (holes between threads/yarns), which reduces filtration [WHO, 2020].

Masks for Singers – Care & Use

The additional care considerations specific to the singer’s mask revolve around the care of the fabrics and materials used and the need to prevent distortions to the mask shape and fit. While some materials (e.g., cotton) may survive the highest heat settings of the washer and dryer, others (e.g., polypropylene and horsehair) may not. In the absence of specific instructions it is best to proceed with care, wash by hand with gentle detergent, and hang to dry in a dry place.

Cleaning versus Disinfecting – Overview

To reduce risks associated with COVID-19 AND other potentially infectious microorganisms (e.g. bacteria, viruses, and fungi) clean and/or disinfect masks before each use. It is important to note that cleaning and disinfection are different processes with different goals.

- Cleaning refers to the physical removal of organic material or soil from objects, with the goal of removing rather than killing microorganisms. Cleaning can be accomplished by hand or machine washing with mild detergent and rinsing with copious amounts of water.

- Disinfecting refers to the destruction of microorganisms by physical processes like heat, or by chemical means. The goal of disinfection is to kill and/or inactivate most microorganisms, but it may not kill everything (AAMI, 1995).

Always check with relevant regulatory officials and manufacturer’s instructions. Click here for more information about cleaning and disinfecting masks.

Washing – Careful hand washing with an unscented detergent at the highest temperature acceptable for the fabrics and materials used in the mask is probably the best choice. Bleach should not be used (inhalation risk). Thoroughly rinse the mask after washing.

Drying – The materials used in the singer’s mask may not allow for machine drying, as drying contributes to faster wear and tear of masks. Hang to dry. Masks should be dried completely and stored in a dry environment since damp masks can become breeding grounds for mold and bacteria. Avoid dryer sheets if machine drying the mask due to residue build-up and skin irritation.

Disinfecting – Avoid the use of sprays to “disinfect” or “renew” the mask (e.g., sprays containing bleach or alcohol). While some may pose an inhalation risk, others may be ineffective and provide a false sense of security. For singer’s masks, which are used infrequently, consider quarantining the mask for at least seven days if heat-based disinfection methods are not compatible with mask components. Note that the materials used in the masks for singers may not allow for high-temperature treatments.

Regular inspection – It is important to examine the materials for any wear and tear before each use. Mask materials are likely to degrade over time and with repeated washing/disinfection cycles. For most reusable fabric masks the exact number of cycles before mask performance degrades is still unknown. Inspect masks carefully for defects and/or damage before each use. Discard masks if any concerns arise. Click here for more information on mask testing you can do at home.

Conclusion

Singing with masks poses unique challenges that masks specifically designed for singers aim to solve. Whether making or buying such a mask, paying extra attention to fit, function, and materials can help ensure the best performance for the performer. Research shows that wearing masks can help reduce the spread of respiratory particles generated by singing. Although we don’t yet know the “perfect” mask, we look forward to working with scientists, singers, and sewists to continue innovating and improving masks for singers as emerging data points the way…

Join the discussion about masks for singers in the comments below or in the Facebook Group, “Masks for Performers.” If you are interested in joining the discussion about nonwoven polypropylene (NWPP) for masks join us in the Facebook Group, “NWPP4Masks.“

Updates

Check out this webinar about about masks for performers (November 12, 2020):

Select References

Special thanks to the Halifax Camerata Singers of Nova Scotia for permission to use an image from the trailer of their performance “Voices of Remembrance” as the banner image for this post. “Voices of Remembrance” is a moving program of music and readings about remembrance that has been recorded for broadcast by Leaf Music and was available on Facebook and YouTube on Tuesday, November 10 at 7:30 p.m.

Can anyone comment on sourcing masks for singers? We are in BC and have heard that there is a supplier in Nanaimo. Anyone know of them?

Would anyone like to comment on singers masks vs brackets and medical masks for comfort?

Hi Kitty, I would encourage you to join the Facebook group “Masks for Performers”. It is linked in the blog post in the “Making or Buying Masks for Singers” section. I’ve also provided the link blow. By joining the group you will have access to the list of Mask Makers, there are 3 in BC and many more across Canada and around the world. Here is the link: https://www.facebook.com/groups/3438493592850143

Where can I find a pattern for the singer mask ?

The pattern for the singer’s mask is provided in the description box of my YouTube tutorials. The description box is easily visible when you are on a desktop or laptop. It can be hard to find on a phone or tablet.

The main tutorial for “Version 3” was filmed in August 2020 and the fabric choices need to be updated. The mask should be 3 layers for all components of the mask (Top, Front, Bottom). At the very least the middle layer should be spunbond non-woven polypropylene (NWPP) at 70 grams per square meter. For best breathability and acoustics it is useful to substitute cotton layers with NWPP layers. For example 2x NWPP + 1x Cotton or even 3x NWPP.

Consider watching the following videos:

Important information update

https://www.youtube.com/watch?v=ZALnsFSRw6M&list=PLaa_wGTk64r032coudU2lXJ-R5qO4kCAi&index=2

New assembly tutorial

https://www.youtube.com/watch?v=TmQeXb7Jhnw&list=PLaa_wGTk64r032coudU2lXJ-R5qO4kCAi

To learn about mask acoustics consider reading: https://makermask.org/mask-acoustics/