MakerMask collaborated with the Energy and Aerosols Laboratory at the University of British Columbia (UBC) to explore filtration and breathability of nonwoven and woven fabrics for reusable masks before and after washing. This post summarizes the key findings. See the paper for details: https://doi.org/10.4209/aaqr.220044

Motivation

Although mask mandates have been rescinded, washable masks remain widely used around the world and offer a sustainable alternative to disposable masks in some situations. This study explores nonwoven and woven fabrics, looking to improve upon the performance of the widespread all-cotton mask. It examines the effects of layering, and of machine washing and drying on their filtration and breathability. This study does not seek replacements for the N95 intended for high risk situations.

Highlights for Sewists

All multilayer sets selected in this study showed improvements over a two-layer woven cotton mask when considering filtration and breathability. However, after washing, none of the material combinations performed nearly as well as a high-quality single-use mask (KF94/KN95/N95). Our findings may serve as useful guidelines for those seeking alternatives to two-layer cotton masks (in terms of both filtration and breathability) as well those seeking alternatives to disposable respirators that are willing to sacrifice higher filtration (e.g., in lower risk situations) and looking to benefit from washability, reuse, beauty, comfort, or fit.

Filtration varies by particle size. Larger particles are easier to filter. We reviewed other studies which show that particles in the 0.5 μm to 5 μm range seem to carry the highest risk of disease transmission.

- For larger particles (>4.2 μm), all layer sets perform well before and after washing (filter 72% to 100%). This is consistent with previous studies showing that most common fabrics filter well >5 μm.

- For submicron particles (less than 1 μm), only the layer sets incorporating Filti or a meltblown nonwoven surgical mask filter over 95% before machine washing. However, post-wash the filtration drops to below 76% at 1 μm and below 42% at 0.5 μm. This is still far better than the roughly 20% filtration at 1 μm of two layers of woven cotton, but inferior to the >94% filtration across all particle sizes provided by KF94/KN95/N95.

Quality factor (Q factor) is a metric combining filtration efficiency and breathability. Overall, nonwoven materials have higher Q factors than woven materials.

- Meltblown nonwovens (N95, surgical masks) have the highest Q factors pre-wash, but degrade significantly after machine washing with detergent and drying. Unwashed meltblown nonwovens are good candidates for double masking.

- Spunbond-meltblown-spunbond (SMS) nonwoven medical wraps, which feature a thin meltblown layer sandwiched between two spunbond layers, have good Q factors pre-wash. Post-wash, multilayer sets with a SMS layer degrade to perform similarly as spunbond nonwoven, likely due to damage to the delicate meltblown layer.

- Spunbond nonwoven polypropylene (SmartFab Thick, OlyFun) and nonwoven polyester (Pellon 930) are next in Q factors. Showing minimal degradation post-wash, they are good candidates for reusable masks. Single-layer spunbond nonwovens filter poorly at submicron level, but layering improves filtration while remaining breathable. Since nonwoven polypropylene (NWPP) has better breathability than cotton, a well-fitting NWPP mask can be a good choice for double masking, with an inner medical mask providing excellent filtration and an outer NWPP mask improving fit with minimal impact on breathability.

- Woven cottons have the lowest Q factors, as they are less breathable than nonwovens. Among cottons, flannel has the highest Q factor.

Finally, we observed performance variability across samples in craft-grade nonwoven materials (SmartFab Thick, OlyFun, Pellon 930) and in Filti.

Study Setup (Methods)

We tested filtration efficiency against particles 0.5 to 5 μm in aerodynamic diameter. Particles in this size range are challenging for fabric masks to capture, and seem to play an important role in SARS-CoV-2 transmission.

- Quality factor (Q factor) of Individual Materials: First, we measured and compared the Q factor of individual materials, including nonwoven polypropylene and nonwoven polyester (craft fabrics, medical masks, and medical wraps), and woven materials (flannel cotton, Kona cotton, sateen cotton).

- Homogeneous Layering: Next, we considered the effect of layering for a subset of materials. We compared the measured results against layering estimations.

- Heterogeneous Layering (Layer Sets): Using materials with high Q factors, we assembled seven multilayer combinations (layer sets) and evaluated their filtration efficiency and pressure drop.

- Effects of Machine Washing Plus IPA Soak: We re-evaluated the layer sets after a washing protocol of 10 cycles of machine washing with detergent, machine drying, and an isopropanol (IPA) soak to remove transient static charge. Please note that MakerMask does NOT recommend IPA soaks for reusable masks.

- Isolating the Impacts of Washing and IPA Soak: Lastly, we isolated the impacts of washing/drying and IPA soak on selective materials–SmartFab, Advancheck (SMS), and Filti. We measured their filtration and pressure drop 1) before treatment, 2) after machine washing and drying, 3) after IPA soak, and 4) after machine washing and drying plus IPA soak.

The paper has more details. Test conditions in this study differ from the NIOSH and ASTM F3502 standards, therefore filtration efficiency and breathability results should not be directly compared.

| Deep Dive: Different Particulate Filtration Efficiency (PFE) Measurements

This study measures size-resolved filtration efficiency, in which PFE is measured at various particle size groups with aerodynamic diameters between 0.5 to 5 μm (e.g., at particle size group 0.5 μm, 0.6 μm, 0.8 μm, …, 5.0 μm). For an even deeper dive, see Sipkens et al., 2022. |

Results

Q Factor of Individual Materials

The materials fall into families with similar Q factors (Table 1), a metric combining filtration and pressure drop (breathability). Meltblown nonwovens have the highest Q factors, followed by Spunbond-Meltblown-Spunbond (SMS) nonwoven medical wraps, craft-grade spunbond nonwoven materials, and woven cottons. Filti varied across samples.

| Material Family | Material | Q Factor [kPa-1] | Pressure Drop [Pa] | Filtration [%] | ||

| 0.5 μm | 1.0 μm | 4.2 μm | ||||

| Meltblown nonwoven | Type 2 Red Cross Surgical Mask 1 | 119 | 44 | 95.6 | 99.4 | 100 |

| Meltblown nonwoven | Halyard Mask | 80 | 11 | 41.7 | 57.0 | 63.2 |

| Meltblown nonwoven | CAN95 IPA respirator 1 | 53 | 47 | 80.2 | 91.3 | 100 |

| Meltblown nonwoven | N95 3M 1860 respirator 1 | 27 | 43 | 49.0 | 67.9 | 97.7 |

| SMS nonwoven | Halyard H400 | 36 | 32 | 41.0 | 71.2 | 99.7 |

| SMS nonwoven | Halyard H100 | 35 | 14 | 16.1 | 39.2 | 77.9 |

| SMS nonwoven | Advancheck SMS Barrier Autoclave Wrap | 13.6 | 24 | 9.9 | 27.1 | 88.5 |

| Craft spunbond nonwoven | SmartFab Thick x 3 3 | 10.7 | 18 | 9.6 | 16.1 | 46.6 |

| Craft spunbond nonwoven | Oly Fun | 10.5 | 7 | 3.3 | 7.7 | 28.1 |

| Craft spunbond nonwoven | Pellon 930 x 5 4 | 8.6 | 10 | 6.6 | 10.4 | 42.6 |

| Woven cotton | Flannel | 8.3 | 25 | 10.5 | 18.2 | 65.2 |

| Woven cotton | Kona | 5 | 16 | 2.0 | 8.8 | 30.4 |

| Woven cotton | Sateen | 4 | 23 | 2.1 | 8.9 | 43 |

| Filti 2 | Filti(2020) 2 | 46 | 10 | 21.8 | 36.2 | 57.4 |

| Filti(2021) 2 | 78 | 47 | 91.6 | 96.0 | 98.4 | |

| Filti(2022) 2 | 101 | 49 | 94.6 | 99.2 | 100 | |

- These materials were treated with isopropanol (IPA) to remove transient static charge.

2. Filti performance varied between batches. “Filti(2020)” was acquired in March 2020, “Filti(2021)” was acquired in March 2021, and “Filti(2022)” was acquired in May 2022.

3. “SmartFab Thick x 3” pressure drop and filtration was measured with 3 layers of SmartFab Thick materials.

4. “Pellon 930 x 5” pressure drop and filtration was measured with 5 layers of Pellon 930.

Table 1. Q Factors of Individual Materials

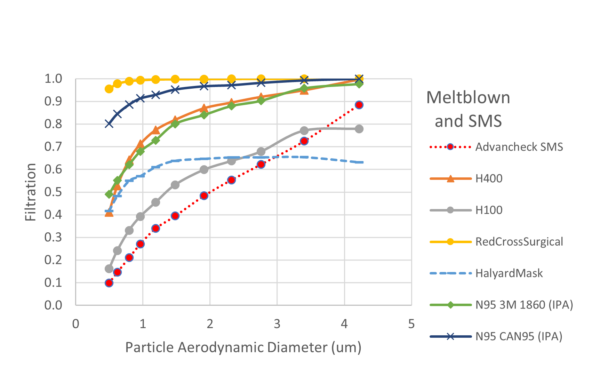

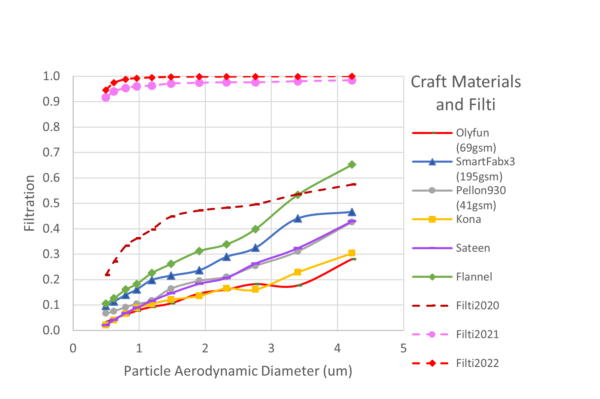

Figure 1a and 1b show the filtration of these individual materials (unwashed) at different particle sizes.

Figure 1a. Filtration vs. Particle Size of Meltblown and SMS Materials (unpublished)

Figure 1b. Filtration vs. Particle Size of Craft Materials and Filti (unpublished)

The Filti mask material varied in performance across samples. Unwashed Filti2020 (acquired in March 2020) only filtered 22% at 0.5 μm. Later samples, Filti2021 (acquired in March 2021) and Filti2022 (acquired in May 2022), filtered significantly better (average 93% at 0.5 μm and 98% at 4.2 μm). Ballard et al. (2021) also observed variability in Filti’s single-layer filtration ranging from 80% to 95% at 0.3 μm.

Homogeneous Layering

For a subset of the materials (SmartFab Thick, OlyFun, Pellon 930, flannel cotton, Advancheck SMS, H400, and H100), we considered the effect of layering on filtration and pressure drop. For each particle size, the multi-layer measurements agreed with calculations from single-layer data per the following model:

- The net penetration for a layered mask is the product of penetration of the individual layers. Penetration (P) is the inverse of filtration (η): P = 1-η.

- The net pressure drop for a layered mask is the sum of each layer.

- The Q factor for a given material is a constant, regardless of the number of layers.

Craft-grade spunbond materials (OlyFun, SmartFab Thick, Pellon 930) showed the largest variations between samples in pressure drop, filtration, and Q factors. Visual inspection under a microscope showed variation in fiber density in localized regions, possibly contributing to this variability.

Heterogeneous Layer Sets

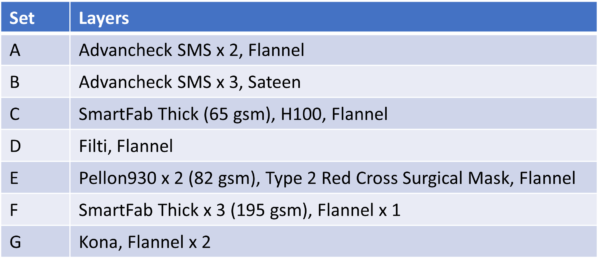

Using materials with high Q factors, and considering the interim guidance of the World Health Organization (WHO) (2020) for non-medical fabric masks, we assembled seven multilayer combinations, or layer sets (Table 2).

Table 2. Heterogeneous Layer Sets

All sets’ net filtration, pressure drop, and Q factors agreed with the layering model estimations as discussed in the homogeneous layering section.

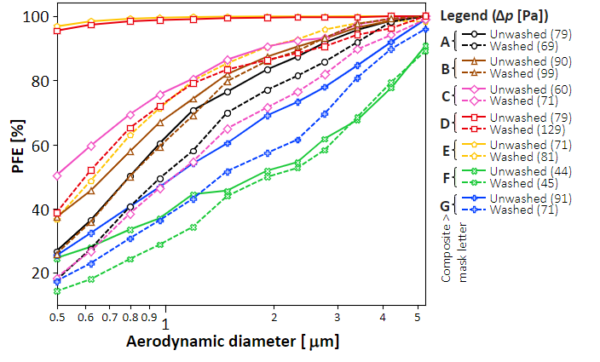

Layer Sets Performance and Effects of Machine Washing

Figure 2 shows the filtration of the layer sets before and after a washing protocol of 10 cycles of machine washing with detergent, machine drying, and an isopropanol soak to remove transient static charge. The horizontal axis shows the particle size groups, and the vertical axis shows the PFE for each particle size group. Performance details are discussed below.

Figure 2. Measured filtration of unwashed (solid) and washed (dotted) layer sets, with pressure drop (Pa, listed in parenthesis) for each in the legend.

All layer sets showed good filtration efficiency (72% to 100%) for larger particles (4.2 μm) before and after washing.

For smaller particles (< 1 μm), before washing,

- Set E (with meltblown nonwoven surgical mask) filtered best, above 95%.

- Set D (with Filti) performed similarly, above 92%.

- Sets C, B, and A (with SMS) were next in performance, although filtering significantly worse than E and D. Within this group, set C (SmartFab Thick, H100, Flannel) filtered and breathed better than sets A and B (with multiple layers of Advancheck SMS).

- In the bottom performance group, Set G (Kona, flannel x 2) filtered better than Set F (SmartFab Thick x 3, flannel), but F was the most breathable set with the lowest pressure drop.

For smaller particles (<1 μm), after machine washing and IPA soak,

- The pre-wash highest performing sets E (with meltblown nonwoven surgical mask), D (with Filti), and C (with H100 SMS) degraded significantly in filtration. This may result from the wash and isopropanol soak neutralizing electrostatic charge in the meltblown and in the proprietary nanofiber technology in Filti. This is unsurprising, as other studies have shown that washing degrades filtration by N95 and medical masks, both of which typically contain meltblown nonwoven polypropylene.

- Sets A, B, F, and G showed moderate decrease in filtration.

In terms of pressure drop (breathability),

- Set F (with spunbond nonwoven polypropylene) was the most breathable with a significantly lower pressure drop than the other sets.

- Sets C, D, E (with meltblown or nanofiber) significantly increased in pressure drop (less breathable) after washing, possibly due to the change in porosity and fiber-density post-wash. These were the same sets that degraded significantly in filtration.

- Sets A, B, and F (with calendered spunbond nonwoven outer layer) showed small changes in pressure drop, possibly because the calendered spunbond nonwoven outer layer provided stability to the fibers.

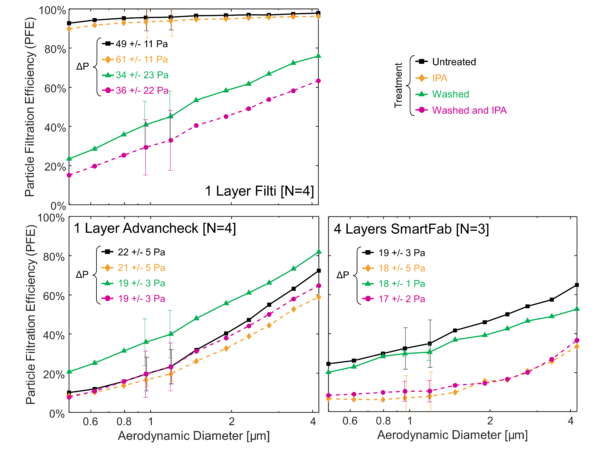

Isolating the Impacts of IPA Soak and Washing

The washing protocol for the above tests included an IPA (isopropanol) soak, which might degrade the performance of the electret materials. The excellent filtration of submicron particles by meltblown non-woven polypropylene in N95 respirators and ASTM-compliant medical masks is thanks to electrets, or electric charge introduced into the material during manufacturing. That electric charge attracts and captures tiny particles. However, that electric charge can be neutralized by alcohol or washing. Additional tests were performed on selective materials (SmartFab, Advancheck, and Filti) to isolate the impacts of washing and IPA soak. Figure 3 shows the results.

Figure 3. Average filtration of Filti, Advancheck, and SmartFab: untreated (black), IPA treated (yellow dash), washed (green), washed and IPA treated (pink dash). ΔP shows average pressure drop. [N = ] represents the number of samples. The uncertainty in pressure and the error bars represent one standard deviation.

Washing and drying produced variable effects, significantly decreasing the filtration of Filti, slightly decreasing the filtration of SmartFab, but potentially improving the filtration of Advancheck SMS.

IPA soak degraded filtration of all three materials, most significantly on SmartFab. MakerMask does NOT recommend IPA soaks for reusable masks (Click here for our post about washing reusable masks).

Summary of Results

Here’s a summary of the key findings.

-

- For individual materials, nonwovens had higher Q factors than woven cottons. Among the woven cottons, flannel performed best.

- Before washing, materials with meltblown nonwoven polypropylene (SMS wrap, N95, surgical masks) had the highest Q factor, outperforming spunbond nonwoven polypropylene (SmartFab Thick, OlyFun) and polyester (Pellon 930).

- Nonwoven craft materials (SmartFab Thick, OlyFun, Pellon 930) showed some variation in filtration and pressure drop between samples.

- Filti showed significant variation in filtration and pressure drop between samples.

- After 10 cycles of machine washing with detergent and machine drying, and a final isopropanol soak, meltblown nonwovens degraded significantly to Q factors similar to spunbond nonwoven. Everts et al., 2021 suggested that gentler wash methods without detergent can reduce degradation.

- Overall, for each particle size group, the measured penetration and pressure drop of the multilayer sets agreed with the calculated layering estimation.

- Nonwovens and cotton flannel offer a substantial improvement over woven cotton masks.

- Selective materials (SmartFab, Advancheck, and Filti) were examined to isolate the impacts of IPA soak and washing/drying. IPA soak degraded filtration of all three materials, while washing and drying produced variable effects.