On December 1, 2020, the World Health Organization (WHO) updated their guidance on fabric masks, “Mask Use in the Context of COVID-19 (December, 2020)”, including their “Updated Guidance on Non-Medical (Fabric) Masks” (p. 19-22). This post pulls out key quotes from the new WHO guidance, touching on their recommendations for layering, mask performance standards, and washing. Followers of other health agencies and organizations around the globe may notice that the field is beginning to converge on more common recommendations, including three-layer masks that include spunbond nonwoven polypropylene (NWPP).

WHO Fabric Mask Guidance

“Non-medical masks are aimed at the general population, primarily for protecting others from exhaled virus-containing droplets emitted by the mask wearer.” The new recommendations emphasize the importance of fit, explaining that “snug fitting designs are suggested as they limit leaks of unfiltered air escaping from the mask (Lustig et al, 2020).”

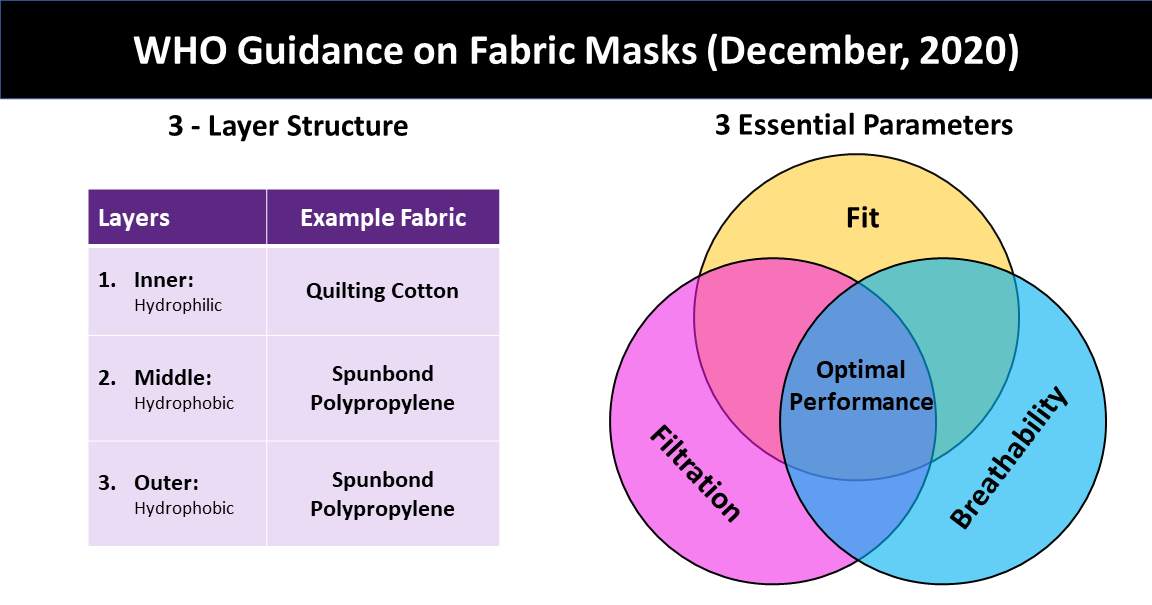

Three Essential Parameters for Fabric Masks

“The essential performance parameters include good breathability, filtration of droplets originating from the wearer, and a snug fit covering the nose and mouth.”

Three Layer Structure Recommended for Fabric Masks

“Homemade non-medical masks made of household fabrics should ideally have a three-layer structure, with each layer providing a function (AATCC, 2020). It should include:”

- Hydrophilic Innermost Layer (e.g., quilting cotton) “an innermost layer (that will be in contact with the face) of a hydrophilic material (e.g., cotton or cotton blends of terry cloth towel, quilting cotton and flannel) that is non-irritating against the skin and can contain droplets (Lustig et al, 2020)”

- Hydrophobic Middle Layer (e.g., spunbond polypropylene) “a middle hydrophobic layer of synthetic breathable non-woven material (spunbond polypropylene, polyester … ), which may enhance filtration, prevent permeation of droplets or retain droplets (Lustig et al, 2020; Zhao et al, 2020) “

- Hydrophobic Outermost Layers (e.g., spunbond polypropylene) “an outermost layer made of hydrophobic material (e.g. spunbond polypropylene, polyester or their blends), which may limit external contamination from penetrating through the layers to the wearer’s nose and mouth and maintains and prevents water accumulation from blocking the pores of the fabric (Lustig et al, 2020).”

Advice on Fabric Selections for Mask Layers

“Non-medical mask construction using breathable fabrics such as cotton, cotton blends, polyesters, nylon and polypropylene spunbond that are breathable may impart adequate filtration performance when layered.” However, “It is important to note that with more tightly woven materials, breathability may be reduced as the number of layers increases.”

“Ideally the mask should not have contact with the lips, unless hydrophobic fabrics are used in at least one layer of the mask (Lustig et al, 2020).”

Things to AvoidAvoid: “Coffee filters, vacuum bags and materials not meant for clothing should be avoided as they may contain injurious content when breathed in.”Antimicrobial additives/fabrics should NOT be used for innermost mask layers: “Treated fabrics must not come into direct contact with mucous membranes; the innermost fabric should not be treated with antimicrobial additives, only the outermost layer… In addition, antimicrobial fabric standards (e.g., ISO 18184, ISO 20743, AATCC TM100, AATCC 100) are generally slow acting. These standards are not appropriate for non-medical cloth masks and may provide a false sense of protection from infectious agents.”Elastic fabrics are NOT preferred: “It is preferable not to select elastic material to make masks as the mask material may be stretched over the face, resulting in increased pore size and lower filtration through multiple usage. Additionally, elastic fabrics are sensitive to washing at high temperatures thus may degrade over time.”Coatings are NOT recommended: “Coating the fabric with compounds like wax may increase the barrier and render the mask fluid resistant; however, such coatings may inadvertently completely block the pores and make the mask difficult to breathe through. In addition to decreased breathability unfiltered air may more likely escape the sides of the mask on exhalation. Coating is therefore not recommended.”Gore-Tex is NOT recommended: “Microporous films such as Gore-Tex are not recommended (AATCC, 2020).”Valves are discouraged: “Valves that let unfiltered air escape the mask are discouraged and are an inappropriate feature for masks used for the purpose of preventing transmission.”Volatile additives are discouraged: “Volatile additives are discouraged as these may pose a health risk when inhaled repeatedly during wear. Certification according to organizations including OEKO-TEX (Europe) or SEK (Japan), and additives complying with REACH (Europe) or the Environmental Protection Agency (EPA, United States of America) indicate that textile additives are safe and added at safe levels.” |

Recommended Washing Instructions for Fabric Masks

In addition to these three essential parameters, for reusable masks there is a fourth critical requirement: the masks must be washable. Recommended washing instructions include (p. 3):

- “Wash fabric masks in soap or detergent and preferably hot water (at least 60° Centigrade/140° Fahrenheit) at least once a day.”

- “If it is not possible to wash the masks in hot water, then wash the mask in soap/detergent and room temperature water, followed by boiling the mask for 1 minute.”

Performance Criteria for Fabric Masks

The WHO provides specific performance criteria for fabric masks for manufacturers and those that have access to formal laboratory testing. However, they recognize that individual makers constructing homemade masks “do not have access to test equipment to confirm target performance (filtration and breathability).” Although individual makers may not have access to testing, a number of groups are investigating the performance of common mask fabrics and sharing them publicly with makers and sewists that aspire to meet the same performance criteria as manufacturers. These performance criteria address filtration, breathability, fit, and washing requirements (p. 20-21):

- Filtration (Filtration Efficiency):

- Minimum Threshold: “70% @ 3um”

- Preferred Threshold: “>70%, without compromising breathability”

- Breathability (Breathing Resistance):

- Minimum Threshold: “≤60 Pa/cm2”

- Preferred Threshold: “Adult: ≤ 40 Pa/cm2, Pediatric: ≤ 20 Pa/cm2”

- Fit (Coverage and Sizing):

- Minimum Threshold – Coverage: “Full coverage of nose and mouth, consistent, snug perimeter fit at the nose bridge, cheeks, chin and lateral sides of the face; adequate surface area to minimize breathing resistance and minimize side leakage.”

- Minimum Threshold – Sizing: “Adult and Child”

- Preferred Threshold – Sizing: “Sizing for adults and children (3-5, 6-9, 10-12, >12)”

- Washing: reusable masks “should include instructions for washing and must be washed a minimum of five cycles, implying initial performance is maintained after each wash cycle.”

- Minimum Threshold: 5 cycles

Standards Organizations

The performance criteria are consistent with freely available cloth mask standards such as those from:

- French Standardization Association (AFNOR Group)

- The European Committee for Standardization (CEN)

- Swiss National COVID-19 Task Force [TESTEX Community Mask]

- The American Association of Textile Chemists and Colorists (AATCC)

- The South Korean Ministry of Food and Drug Safety (MFDS)

- The Italian Standardization Body (UNI)

- The Government of Bangladesh.

How many masks should I wear per day? “The AFNOR document recommends using a barrier mask for a maximum period of 4 hours. Therefore a person who works outside of his/her home may anticipate having 3 per day: 1 for the morning, 1 for the afternoon and possibly 1 as a backup. Note: don’t forget to wash your hands… before putting a mask on and after removing it.” – AFNOR 2020

Información Adicional

For more information about using spunbond nonwoven polypropylene in masks, check out MakerMask.org

Previous MakerMask Posts About WHO Fabric Mask Guidance

- Adopting WHO Guidance on Fabric Masks for COVID-19 (July, 2020)

- WHO Guidance on Face Masks Changes (June, 2020)

Select References

- Lustig SR, Biswakarma JJH, Rana D, Tilford SH, Hu W, Su M, et al. Effectiveness of Common Fabrics to Block Aqueous Aerosols of Virus-like Nanoparticles. ACS Nano. 2020;14(6):7651-8. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7263076/

- Zangmeister CD, Radney JG, Vicenzi EP, Weaver JL. Filtration Efficiencies of Nanoscale Aerosol by Cloth Mask Materials Used to Slow the Spread of SARS-CoV-2. ACS Nano. 2020;14(7):9188-200. https://pubs.acs.org/doi/10.1021/acsnano.0c05025

- Zhao M, Liao L, Xiao W, Yu X, Wang H, Wang Q, et al. Household materials selection for homemade cloth face coverings and their filtration efficiency enhancement with triboelectric charging. Nano Lett. 2020; 20(7):5544-5552. https://pubs.acs.org/doi/10.1021/acs.nanolett.0c02211

- AATCC. AATCC M14-2020 Guidance and Considerations for General Purpose Textile Face Coverings: Adult (https://www.aatcc.org/covid/ accessed 28 November 2020)

4 pensamientos en “WHO Fabric Mask Guidance – December Updates”

Comentarios cerrados.